The FGX technology provides an innovative and cost-effective dry coal processing process that integrates the separation principles of an autogenous medium separator and a conventional table concentrator. Three product streams including deshaled product, middlings and tailing streams are obtained through this process. Two dust collection mechanisms are employed, making the technology environmentally friendly.

The FGX dry processing of coal is a density based method. A typical FGX separator consists of a coal feeder, separating compartment, blower, draft fan, and dust collecting system. The separating compartment includes a perforated deck, vibrators, air chamber, and hanging mechanism. FGX has sold over 2,000 units in over 17 countries around the world proving its success in cleaning coal from various regions.

Table 1. FGX Compound Dry Coal Cleaning Equipment

| Model | Feed size (mm) | Capacity (t/h) | Dimension (ft,in) | Power, kW |

|---|---|---|---|---|

| FGX-1 | 60-0 | ~10 | 18’8″ x 10’3″ x 19’6″ | 24.28 |

| FGX-2 | 60-0 | ~20 | 24’9″ x 22’8″ x 21’11” | 59.81 |

| FGX-3 | 80-0 | ~30 | 30’2″ x 27’3″ x 28’7″ | 73.57 |

| FGX-6 | 80-0 | ~60 | 37’3″ x 35′ x 30’4″ | 146.57 |

| FGX-9 | 80-0 | ~90 | 42’3″ x 39’5″ x 31’2″ | 274.04 |

| FGX-12 | 80-0 | ~120 | 46’6″ x 43’3″ x 31’6″ | 328.04 |

| FGX-18A | 80-0 | ~180 | 61’5″ x 46’8″ x 31’2″ | 499.71 |

| FGX-24A | 80-0 | ~240 | 75’7″ x 48’2″ x 31’6″ | 656.08 |

| FGX-24 | 80-0 | ~240 | 62’8″ x 47’8″ x 38’6″ | 645.99 |

| FGX-48A | 80-0 | ~480 | 83’5″ x 68’6″ x 38’6″ | 1300.82 |

NOTES: 1. Feed surface moisture should be less than 9%.

2. Models with “A” are dual systems, e.g., FGX-18A consists of two FGX-9s.

3. Dry Coal Separators specifications subject to change without notice.

Table 2. ZM High Efficiency Mineral Separator

| Model | Feed size (mm) | Capacity (t/h) | Power, kW |

|---|---|---|---|

| ZM15 | 50-0 | 15 | 36 |

| ZM35 | 70-0 | 33 | 108 |

| ZM70 | 70-0 | 70 | 180 |

| ZM150 | 90-0 | 150 | 375 |

| ZM200 | 110-0 | 200 | 650 |

| ZM400 | 110-0 | 400 | 1250 |

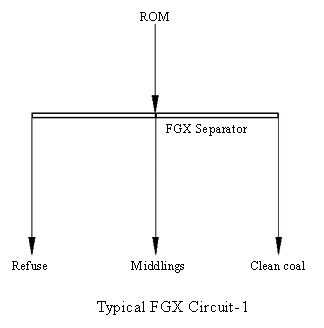

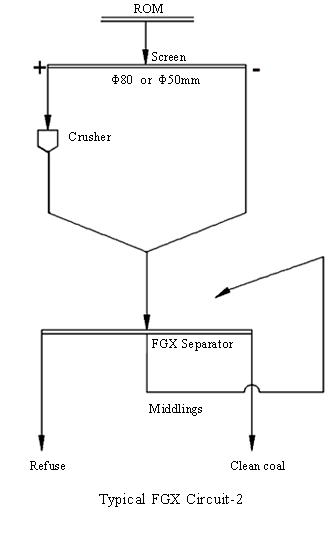

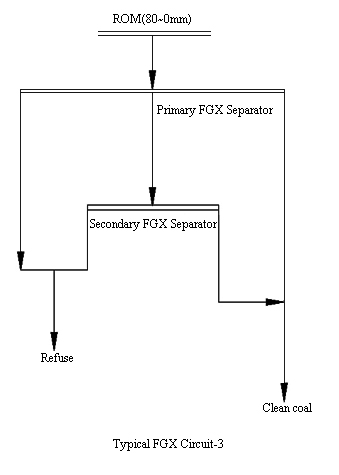

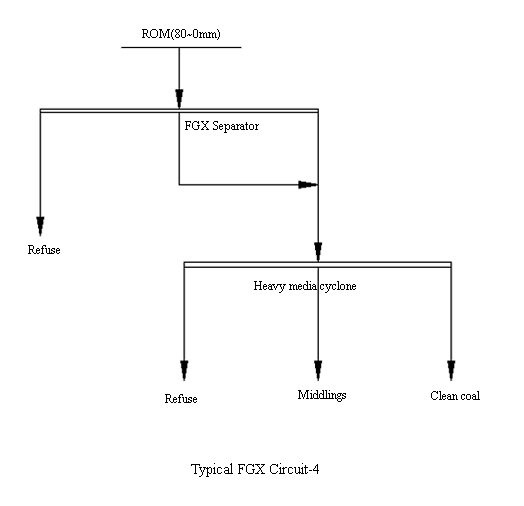

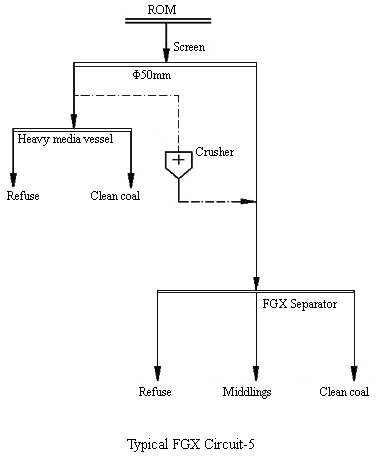

Typical FGX Circuits