In many areas of the United States water is a scarce resource and very expensive to use in the coal preparation process. Not only is the water itself expensive, but it is extremely difficult to obtain permitting for a water plant under today’s regulations. FGX technology provides a cost effective solution that yields high quality results, while requiring only an air quality permit.

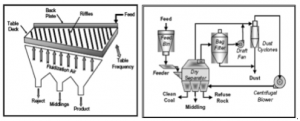

FGX is in a class of its own when it comes to dry coal preparation as it is a highly efficient, density based process. A typical FGX separator consists of a coal feeder, separating compartment, blower, draft fan, and dust collecting system. The separating compartment consists of a table, vibrator, air chamber, and hanging mechanism. The angle and pitch of the perforated table can be adjusted, as can the frequency and amount of air flow through each quadrant of the table. Figure 1 and 2 below show the components of a typical FGX separator and the separating compartment, respectively.

Figure 1 Figure 2

Coal particles are introduced onto the vibrating table and form a fluidized bed with the help of air provided by the blower. The high density rocks form the bottom layer of the table with low density coal forming the top layer. The table vibration and constant feed of new material cause the low density coal particles to be discharged along the front of the table while the high density rock particles move upward and inward toward the discharge end of the table.

As a completely dry process, FGX technology efficiently cleans coal without the use of water, saving you money on water costs and water treatment. In many cases, a marketable product is produced by an FGX Separator, eliminating the need for an expensive wet preparation plant.